|

Hydro Flex Hose (Western) Limited

9624-45 Ave, Edmonton AB T6E 5Y9

Ph: (780) 436-9271 Fax: (780) 436-8601 |

Pipe Penetration Seals

Waterseal

The Pipeseal Waterseal provides an economincal and sure method of sealing pipes and conduit through walls and floors for 20 psig. Choice first starts with materials. Three types of rubber, and two types of metal hardware are available. For most applications, EPDM is the proper choice, but Nitrile is best if the seal may be exposed to hydrocarbons. Stainless steel hardware can also be used in areas where corrosion is a tougher problem. And Silicone is the choice for high temperature applications. (currently not shown in the table below.) After choosing materials, you determine which model and how many links will be needed. Assistance can be provided, or the sizing program below can be used.

Type & Materials

| TYPE |

SEAL MATERIAL |

PRESSURE PLATES |

BOLTS & NUTS |

TEMP RANGE |

APPLICATIONS |

| E |

EPDM |

Glass Reinforced Plastic |

Steel zinc dichoromate |

-40 to +250 |

Suitable for most applications in water, both above ground and direct burial. Provides electrical insulation where cathodic protection is required. |

| ES |

EPDM |

Glass Reinforced Plastic |

316 Stainless Steel |

-40 to +250 |

Suitable for environments where the corrosion resistance of stainless steel hardware is required. |

| N |

NITRILE |

Glass Reinforced Plastic |

Steel zinc dichoromate |

-40 to +210 |

Resistant to most hydrocarbons, oil, gas, jet fuel, and many solvents. |

| NS |

NITRILE |

Glass Reinforced Plastic |

316 Stainless Steel |

-40 to +210 |

Same as above but with the corrosion resistance of stainless steel hardware. |

|

|

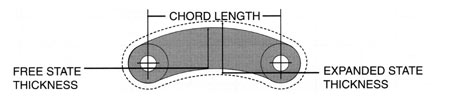

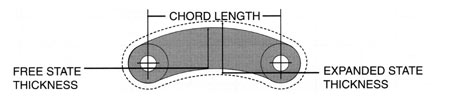

Models & Dimensional Information

| Pipeseal Size |

Free State

Thickness (in) |

Expanded State

Thickness (in) |

Chord Length

(in) |

| PS-200 |

0.50 |

0.62 |

1.125 |

| PS-275 |

0.62 |

0.78 |

0.910 |

| PS-300 |

0.71 |

0.88 |

1.51 |

| PS-315 |

0.82 |

1.03 |

1.47 |

| PS-325 |

0.94 |

1.18 |

3.1 |

| PS-400 |

1.43 |

1.81 |

3.625 |

| PS-425 |

1.13 |

1.45 |

3.625 |

| PS-475 |

1.62 |

1.90 |

2.625 |

| PS-500 |

2.37 |

2.81 |

3.86 |

| PS-525 |

2.18 |

2.5 |

3.86 |

| PS-575 |

1.18 |

2.35 |

3.1 |

| PS-600 |

3.20 |

4.0 |

6.0 |

|

|

|

|

|

1. Wrap the belt

around the pipe.

Then connect

the first and last

links. |

|

2. Slide the

assembly into

the space

between the pipe and wall. |

|

3. Gradually

and sequentially

tighten the bolts.

Tighten each

bolt 2-3 turns

making 5 to 9

passes com-

pletely around

the pipe. |

|

Information and Specifications courtesy of www.flexicraft.com |